SRAM’s AXS T-Type drivetrains have seemingly taken over OEM spec on everything from cross-country race bikes to burly Enduro eMTBs — which to be clear, I’m not complaining about as I’m generally a fan — but I do have a couple of niggles…

Many will remember when SRAM released the T-Type Transmission drivetrain because the internet was peppered with photos and videos of people standing on the new derailleurs with the bikes lying on their sides. SRAM makes a big deal about the strength of their direct mount technology, and rightfully so, because it’s easy to tell that it’s a much stronger interface than what a standard derailleur hanger can offer — just try pushing on the derailleur by hand and the difference is immediately noticeable. The touted benefits are increased shift accuracy under load and easier setup due to the elimination of derailleur adjustment screws.

That said, the standing-on-a-derailleur party trick isn’t reflective of the principal weak point in most derailleurs — the low-hanging cage. And if we’re being honest, you’re mostly just standing on the axle, given the way SRAM’s Full Mount system ties the derailleur into it.

I’ll get to my niggles with the setup in a bit since my number one complaint with the Transmission ecosystem is how susceptible the derailleur cages are to damage. Historically, I have a really good track record not breaking rear derailleurs, but I’ve unfortunately already damaged two T-Type Transmission cages. The strength and stiffness of the direct mount system are certainly beneficial to shifting performance, but that rigidity now means the brunt of impacts has to be shouldered by the derailleur, and not the hanger.

SRAM — of course — has thought about that, which is why there is an override clutch designed to react to impacts by allowing the derailleur to go “limp” in the event of an impact. And to be clear, the override clutch works amazingly well when the derailleur is impacted from the outboard side, forcing the derailleur inboard — and that’s how most impacts occur. However, the opposite is true when the derailleur is impacted from the inboard side, forcing it outward. From what I can tell from bench testing, the override clutch doesn’t seem to do anything in that direction, which is also substantiated by the number of outwardly bent derailleur cages I’ve personally experienced, in addition to the growing number of similarly bent cages I’ve seen and heard about.

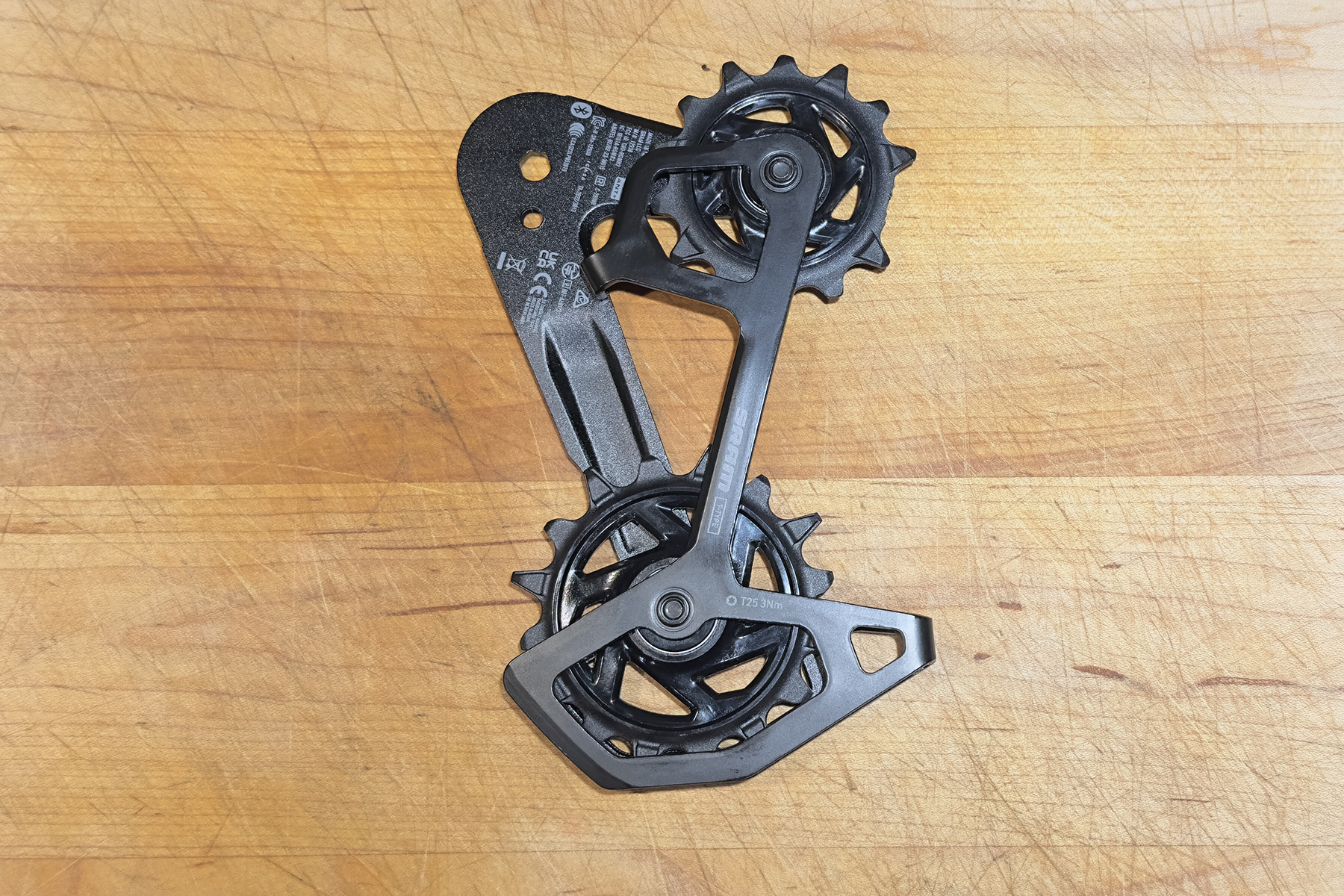

What doesn’t help is that T-Type Transmission cages aren’t straight to begin with, featuring a deliberate bend in the middle to smooth out chain routing. That, in conjunction with how close to the ground the cage sits (especially with 27.5 rear wheels), makes them quite susceptible to catching rocks on the inside of the cage. Since the clutch isn’t going to bail the cage out in those scenarios, it’s easy to mangle one with the right impact.

All this to say that SRAM’s Universal T-Type Replacement Derailleur Cages are a welcome and economical option. The aluminum version is super cheap, with an MSRP of $29, and there are big savings (relatively speaking, anyway) on the carbon versions too, which come in at $100.

Now, the reason the Universal T-Type Replacement Derailleur Cages cost significantly less than the ones mentioned above is that they don’t come with the damper mechanism (i.e., the clutch). You re-use the likely undamaged damper mechanism from the bent cage, and by following the recommended sequence to the disassembly and reassembly process, the damper mechanism actually stays in the derailleur body — check out SRAM’s tutorial video for details. Additionally, SRAM includes new fasteners and the necessary 3 mm security hex bit.

I’m considering putting one in my pack just like I’ve done for decades with derailleur hangers. Oh, and I almost forgot, the $29 aluminum cage even comes with new pulleys — nicely done SRAM.

[David Golay: those replacement pulleys are especially welcome because I’ve found that, once the narrow-wide tooth profile on the tension pulley wears down a bit, it’s possible to have the chain skip off the pulley in rough terrain and wind up with the narrow chain links on the wide pulley teeth, which predictably does not do great things to the drivetrain performance. Resetting it only takes a moment trailside, but it’s still pretty annoying.]

Ok, now onto the derailleur setup procedure: I agree with SRAM that the setup process eliminates some common mistakes like improperly set up B-gap and limit screws, but I find the whole process tricky to remember, and it’s crucial to follow the steps in the right order. Plus, since chain length, setup cog, and derailleur cage position (A or B) are specific to the bike in question (SRAM has a fairly complete, but not all-encompassing database of bikes), I have to reference the setup guide nearly every time I do it. Honestly, I find the whole process rather esoteric, and I’ve been working on bikes professionally for over twenty-five years.

Additionally, I think a lot of folks who have purchased T-Type Transmission-equipped bikes have no idea that there is a very important setup procedure to follow. I’ve seen a lot of improperly set up T-Type derailleurs, and find myself routinely answering questions and helping friends whose drivetrains have “come out of adjustment” and are shifting poorly. From what I’ve seen, the majority of these issues occur after the rear wheel has been removed and reinstalled after a flat repair, tire change, etc — in these situations, the derailleur can get knocked out of position, which isn’t all that noticeable, but completely wrecks the shifting performance. The fix is fairly straightforward (if you are aware of it) since the chain is already sized and the derailleur is mounted: follow the final steps of the setup procedure where you put the derailleur cage in the setup position, then with the chain in the setup cog, pull the derailleur rearward to remove the slack in the chain, rotate the crank two revolutions, torque the fixing bolt, and then check that the alignment marks are aligned correctly. Again, it’s a bit nuanced and requires you to know which setup position to use on the derailleur, and which setup cog your bike uses.

So, in summary, my advice to everyone who has a bike with a SRAM Transmission-equipped bike is to familiarize yourself with the setup procedure, be careful when removing the rear wheel, and maybe pick up one of the $29 replacement cages, just in case.

“but that rigidity now means the brunt of impacts has to be shouldered by the derailleur, and not the hanger.”

Finally, somebody gets it!

“The fix is fairly straightforward (if you are aware of it) since the chain is already sized and the derailleur is mounted: follow the final steps of the setup procedure where you put the derailleur cage in the setup position, then with the chain in the setup cog, pull the derailleur rearward to remove the slack in the chain, rotate the crank two revolutions, torque the fixing bolt, and then check that the alignment marks are aligned correctly.”

I probably CAN do this on the trail, but sure don’t want to, and my wife and majority of my riding friends would have no hope whatsoever.

I’ve almost always seen the benefits of new mtb tech. No retrogrouchiness here. But T-Type is never going to find a home in my garage. I’ll stick with regular old AXS or (gasp) switch to Shimano stuff.

Sorry for the rant. Great article BTW!

Hey, I’m a huge fan of the T-Type. It shifts well under pedal load, and is built to handle the torque of us old school big ring mashers (or maybe also e-bike riders who can’t hit triple digit watts without help – I don’t judge). I just know that I have T-Type on both my bikes and have over 1500 miles on the XO version between the two. No issues and no big crashes, so no damage on mine so far. Both of my cages appear the same as the photo in this article. David does a nice job of noting that the cage is not supposed to be parallel to the wheel or chainlink, or many other visual reference points we are accustomed to.

The cage alignment is skewed by design. This lets the lower pulley always aim at the chainring across the gear range of a large cassette. Don’t get fooled into thinking your cage is bent when it’s just “designed”. See the SRAM support article here -> https://support.sram.com/hc/en-us/articles/13826425185051-The-SRAM-Eagle-AXS-Transmission-derailleur-cage-looks-bent-is-this-normal

Whatever you ride, enjoy the trail!