Intro

There is a dizzying array of mountain bike hubs available on the market, spanning a massive price range. So what actually makes a given hub different from another, what do you get by spending more on fancier options, and should you care? We’ve received a bunch of questions on the subject, so we figured an overview of what differentiates higher-end hubs from their less-expensive counterparts would be useful.

This isn’t intended to be a comprehensive overview of specific hub models; rather, we’re looking to give more general guidelines on what to look for in a set of hubs.

Anatomy of a Hub

First off, we’ll go over the very basic construction of most hubs and how they work:

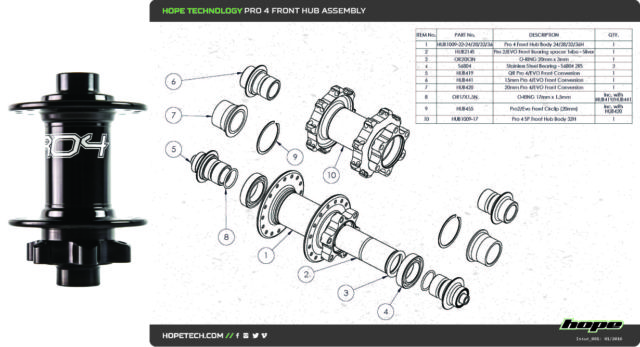

Front hubs, in particular, are quite simple overall. The main components are:

- Hub shell / body. The main exterior component of the hub, through which the spokes are laced and the brake rotor is attached (if applicable). Both “shell” and “body” are used interchangeably as terms.

- Bearings: Front hubs usually use two bearings, one per side. Sealed cartridge bearings are by far the most common style in modern hubs.

- End caps: The parts of the hub that interface with the fork dropouts to position the wheel in the fork. These are often interchangeable to adapt a hub to different axle standards

- Bearing sleeve or axle: A sleeve that goes between the two hub bearings, to support them and interface with the fork axle. The end caps usually attach to the bearing sleeve.

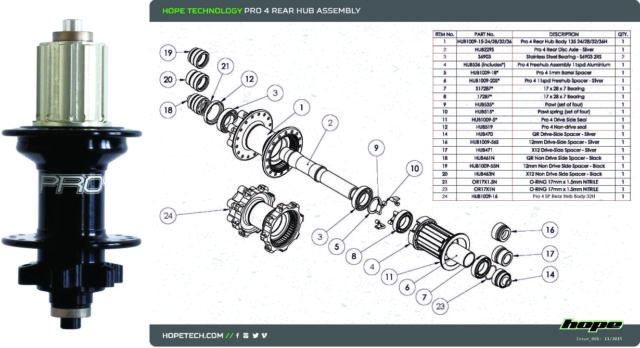

Rear hubs get a little more complicated. In addition to the responsibilities of a front hub (spin, hold the wheel together and in the frame, attach the brake rotor), a rear hub also has to transmit torque from the cranks to the rear wheel, while also allowing the bike to coast without turning the cranks forward. [Except for fixed-gear bikes, of course. If you’re riding a fixie on mountain bike trails, props, I think, but also you’re a maniac.] To handle those extra duties, a rear hub has all the same components as a front hub, and adds the following:

- Freehub Body: The freehub body is the part of the hub that the drivetrain’s cassette attaches to. It will contain a couple of extra bearings, beyond what is found in a front hub, so that it can spin independently of the hub shell, and interfaces to the hub shell via a ratchet mechanism of some sort in order to transfer power to the cassette.

- Ratchet Mechanism: A device that allows the freehub body to spin independently of the hub shell in one direction (when coasting) but that locks the two together to transmit drive torque when the freehub body tries to turn faster than the hub shell in the forward direction (clockwise, when looking at the bike from the drive side). In other words, it lets you coast when you want but then transfers power from your pedals to your cassette / rear wheel. The three main types of ratchet mechanisms are described in more detail below. Sprag clutches feel more different than pawl and ring-drive systems since sprag clutches don’t have individual teeth that mesh together and therefore no specific points around the hub. Pawl and ring-drive systems work a bit differently, but generally aren’t terribly different in terms of the on-trail riding experience.

Hub Terminology

Now we’ll define a few more of the common terms used to describe hubs.

Axle Standard

The dimensions of the axle that a hub is designed to work with. These are typically given as a width (of the hub, between the faces that touch the dropouts of the frame or fork) and a diameter (of the axle that’s designed to fit through the hub for a through-axle hub, or the hub axle itself in the case of classic quick-release hubs).

For example, a 110 x 15 mm front hub is 110 mm wide, and accepts a 15mm-diameter axle. The appropriate axle standard for a given hub is determined by the frame or fork that the hub is intended to be used with, so this is something you’ll want to learn about your bike / fork before buying a new hub.

Boost

A new set of axle standards for both frames and forks that the industry introduced in 2015. The Boost standard features wider axle spacing than traditional hubs. Most current mountain bikes use Boost spacing.

Freehub Body

As noted above, this is the part of a rear hub that the drivetrain’s cassette attaches to. On many hubs, it’s possible to swap freehub bodies to convert between these different standards without having to get an entirely new hub. There are three main standards for freehub body interfaces that are used on mountain bikes:

- Hyper Glide: for Shimano drivetrains with 11 or fewer cassette gears, Sram drivetrains with 10 or fewer gears, and some lower-end 11- and 12-speed Sram cassettes.

- XD: for higher-end Sram 11- and 12-speed cassettes.

- Micro Spline: for Shimano 12-speed drivetrains.

Pawls

Small ratcheting teeth that are actuated by a spring and engage a toothed ring in the hub to transmit torque from the freehub body to the wheel. These are the most common, but not the only, mechanism for designing a ratcheting freehub.

Ring Drive

A catch-all term for a variety of ratchet mechanism styles that use meshing, toothed rings instead of pawls. Chris King and DT (on their higher-end hubs) are the most common purveyors of ring-drive designs.

Sprag Clutch

Effectively a one-way roller bearing that replaces a ratchet mechanism in certain hubs. Onyx is the biggest brand offering hubs of this design. Sprag clutches are silent and offer almost instantaneous engagement, but generally come with a significant weight penalty.

Points of Engagement

The number of points at which a rear hub’s ratchet mechanism engages per revolution of the cassette. Generally abbreviated to POE. Lower-end hubs will generally have something in the range of 18-24 POE. Higher-end hubs typically start at ~36 POE, and go up from there.

For a pawl hub, the number of POE depends on the number of teeth in the ratchet ring in the hub body and the fraction of the total number of pawls that are engaged at a given time. For the simplest example, a hub with a 36-tooth ratchet ring that engages all of its pawls at once would have 36 POE.

However, some hubs increase the number of POE by splitting the pawls into groups that engage in a staggered fashion. For example, a 72 POE Hadley hub has a 36-tooth ratchet ring and four pawls, which engage in pairs of two, doubling the POE from 36 to 72. When one pair of pawls is engaged, the other pair is halfway between teeth on the ratchet ring, and they trade off back and forth to speed up engagement. Since all the teeth in a ring drive are designed to engage at the same time, the number of POE is simply the number of teeth on the rings.

Why Spend More on Hubs?

In general (with some exceptions, which I’ll touch on in a bit), the following are true of higher-end hubs:

- They’re lighter.

- They’re more durable / last longer.

- They tend to be more serviceable, and have better availability of replacement parts.

- They offer more points of engagement.

- They feature better, smoother-running bearings and better sealing from the elements.

- They come in lots of shiny anodized colors.

How much do those things actually matter? Let’s go through them in order:

Weight

Generally, hubs are not the most efficient place to cut weight on a bike, from a grams-per-dollar perspective. That said, hub weight is a bit more important than weight in other places on a bike for two reasons.

First, because hub weight is rotating weight (which has a bigger impact on ride feel than weight in other areas) cutting weight in hubs is a little more impactful than losing that same amount of weight in, say, a handlebar. It’s important to note, though, that hub weight matters far less than rotating mass at the outside of the wheel, such as rims and tires.

Second, hub weight is important because it’s unsprung weight, and thus has a significant impact on suspension performance, unlike small changes in sprung weight like that in the front triangle of your bike (for way more on the concept of unsprung weight and its on-trail effects, check out our review of the Zerode Taniwha Trail).

Furthermore, higher-end hubs can be a nice place to cut weight without any real performance or durability downsides (as compared to areas like suspension, brakes, and tires, where cutting weight tends to come at far more of a compromise in terms of overall performance).

Durability

Higher-end hubs do, generally, last longer and require less service than cheaper ones. Their higher quality bearings last longer, and higher-end hubs generally have better secondary sealing built into the hubs themselves (instead of just relying on the seals on the cartridge bearings) for resistance to grit and water intrusion. High-end hubs also generally have more robust freehub ratchet mechanisms, which can hold up to many years of use with occasional basic maintenance.

Serviceability

If your current hubs haven’t blown up yet, I wouldn’t say you should rush out to buy new ones just because you could theoretically service the new ones when they do break down; this one is probably better looked at as a consideration when you’re definitely buying new hubs / wheels regardless. A high-end hubset can last for decades with a bit of routine maintenance — at least provided that hub standards don’t change as to make them obsolete. I’ve got a pair of somewhat higher-end Hadley hubs that I bought used something like 15 years ago, which have been in regular use for the duration of my ownership, and are still trucking right along. I’ve lost track of how many rims I’ve destroyed on them at this point, but I’ve kept on lacing new ones to those same hubs.

Maybe someday I’ll have to retire them due to changing standards, but the good news on that front is that, thus far, the trend in standards has been towards going wider. In a lot of cases, mid- to high-end, non-Boost hubs can actually be converted to Boost with a new axle and a brake-rotor spacer. There are limits of course, and the reverse isn’t generally true (it doesn’t really work to make a hub narrower than it started out).

Points of Engagement

Faster-engaging hubs, with more points of engagement, are nice when you’re trying to climb something technical and have to move your feet / cranks back and forth to avoid smashing the pedals into rocks and the like, but want to keep putting power down as much as possible. When you have limited space to take a pedal stroke, a hub with more points of engagement lets you actually use more of that range to propel the bike forward, instead of pedaling through “dead” or non-driving stroke before the hub engages. Basically, it lets you turn your leg power into wheel movement with less of a delay.

That said, I’m of the opinion that this becomes a case of diminishing returns pretty quickly. I’m generally ok with anything with at least 36 POE or so; beyond 72 or thereabouts, the differences become fairly subtle. That’s not to say that going with a hub with higher POE makes no difference, but it’s not a massive one, and only crops up in somewhat specific situations. The more technical climbing you’re doing, the more faster-engaging hubs matter.

The downside of a fast-engaging hub is that it can lead to more interaction between the suspension and the pedals in the form of pedal kickback, especially at lower speeds. I don’t want to get too far in the weeds on this particular topic, in the interest of keeping this article brief, but if you’ve ever heard a discussion of how rear suspension feels better when you take off your chain, this is getting at the same issue.

It’s also worth noting that hubs with more POE generally end up having finer-sized teeth (be it in pawls or a ring-drive system) in order to package more POE into a similar amount of space, which can make them somewhat more delicate and fragile. That’s not to say that super high-engagement hubs categorically don’t hold up as well, but there is something of a tradeoff on that point.

Bearing Quality

The advantages of higher-end bearings from a durability and sealing standpoint are real, but I’m generally skeptical of companies’ claims about those nicer bearings offering noticeably reduced drag and the like on a mountain bike. Sure, maybe fancy ceramic bearings do spin a little more smoothly at super high speeds in lab testing, but compared to things like tire rolling resistance on a mountain bike, the difference is minute.

Colors

High-end hubs often come in a lot of them. I like simple silver or black. Your mileage may vary.

Bottom Line

Hubs are certainly not the first place I’d personally look to upgrade most bikes, but higher-end hubs do offer some genuine performance improvements. And given that they can last for decades (even under hard use), there’s a real case to be made for high-end hubs as an investment that might actually end up paying off in the long run. Taking one more component out of the picture when it comes to likely points of failure on a mountain bike has real value as well. More points of engagement can be nice in some situations too, though I’d argue that the fascination with maximizing POE in high-end hubs is a bit overblown and becomes a case of rapidly diminishing returns.

In the end, as with most gear, whether or not a more expensive hub makes sense for you will ultimately come down to your priorities. So we hope that this article has made it a bit easier to sort out those priorities and weigh them with cost next time you’re considering a new hub or evaluating the hubs on a new bike build.

I had 36 POE hubs for years. They worked just fine for my XC marathon with a lot of moderate technical climbing. Today I got a 40 POE hub and I am sure it would be more than enough. But I do understand that some might be amazed by the three digit POE hubs. I mean, MTB is a hobby for most of us, hobby means love and love means a bit of irrationality. On the other hand, hub brands have two big reasons to push for more POE: marketing ploy over their competitors and increased chance user needs a replacement inners sooner because more POE can mean shorter service life.

Technically speaking I believe star ratchet (DT) came out first and Chris King took that idea and created the ring drive. I have both and while the sound and bling factor are certainly worthy points towards CK, the cost and serviceability of DT is also a big selling point. I can get (in the EU) DT 240’s front and rear for the same price as a CK front hub.

Something that was not commented on in the article is that the greater the POE, the greater the durability of the cassette and the chain, due to the leverage effect that over time stretches the chain and wears out the teeth of the entire set.