Enve’s Fifth-Generation M-Series Wheels

Intended Use: XC Race

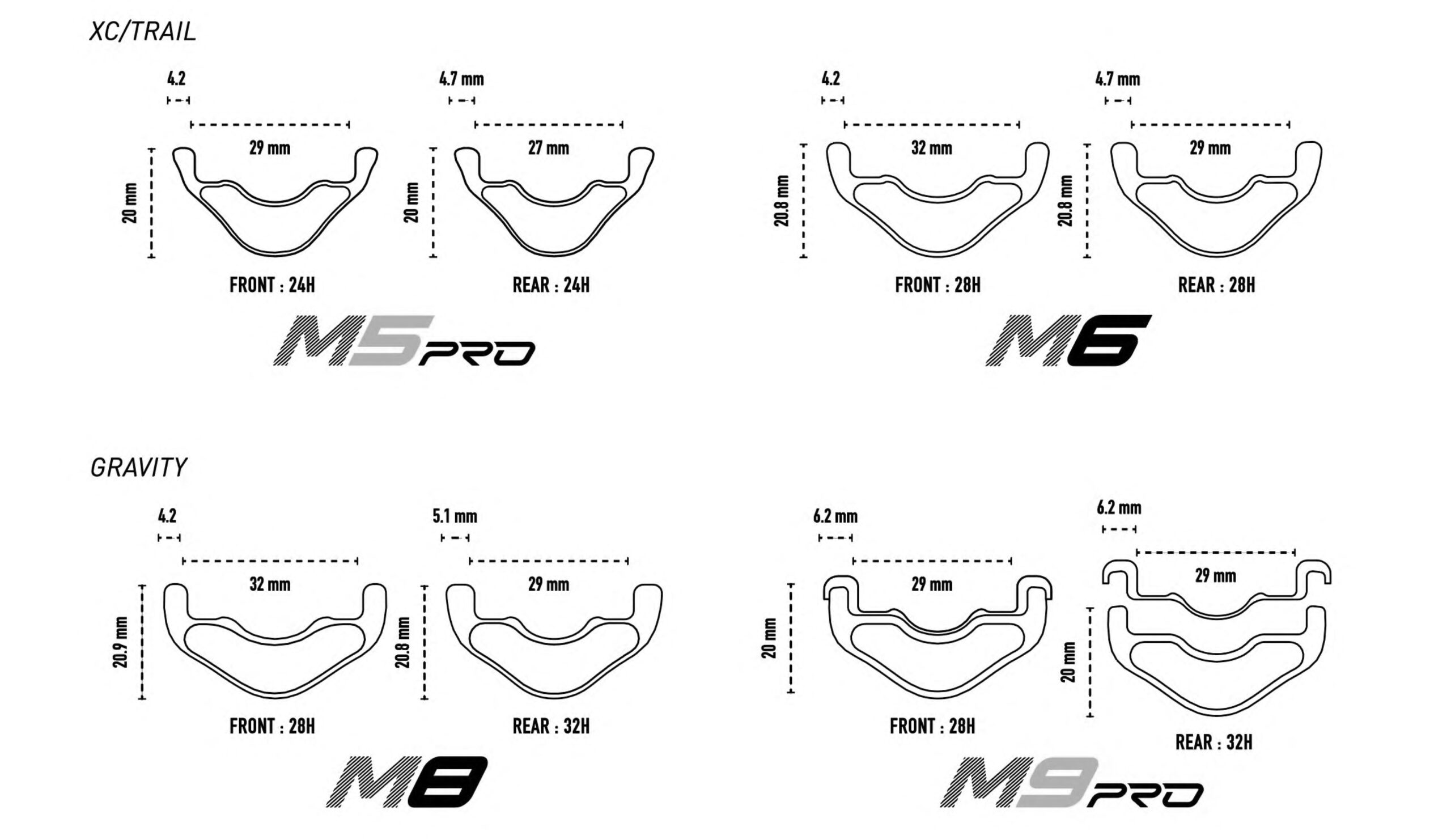

Internal Width: 29 mm (front) / 27 mm (rear)

Versions Available:

- Front: 29’’ only; 15 x 110 mm axle

- Rear: 29’’ only; 12 x 148 mm axle

Rim Material: Carbon Fiber

Stated Weights:

- M5 Pro Front Rim: 343 g

- M5 Pro Rear Rim: 360 g

- M5 Pro Wheelset: 1,341 g

MSRP: $2,300

Intended Use: Trail

Internal Width: 32 mm (front) / 29 mm (rear)

Versions Available:

- Front: 29’’ only; 15 x 110 mm axle

- Rear: 27.5’’ or 29’’; 12 x 148 mm or 12 x 157 mm axle

Rim Material: Carbon Fiber

Stated Weights:

- M6 Front Rim: 426 g

- M6 Rear Rim: 445 g (29’’)

- M6 Wheelset: 1,589 g (29’’)

Blister’s Measured Weights (including tape and valves):

- M6 Front Wheel: 748 g

- M6 Rear Wheel: 872 g (29’’)

- M6 Wheelset: 1,620 g (29’’)

MSRP: $2,300

Intended Use: Enduro

Internal Width: 32 mm (front) / 29 mm (rear)

Versions Available:

- Front: 29’’ only; 15 x 110 mm or 20 x 110 mm axle

- Rear: 27.5’’ or 29’’; 12 x 148 mm or 12 x 157 mm axle

Rim Material: Carbon Fiber

Stated Weights:

- M8 Front Rim: 573 g

- M8 Rear Rim: 585 g (29’’)

- M8 Wheelset: 1,983 g (29’’)

MSRP: $2,300

Intended Use: Enduro / DH Race

Internal Width: 29 mm

Versions Available:

- Front: 29’’ only; 15 x 110 mm or 20 x 110 mm axle

- Rear: 27.5’’ or 29’’; 12 x 148 mm or 12 x 157 mm axle

Rim Material: Carbon Fiber

Stated Weights:

- M9 Pro Front Rim: 720 g

- M9 Pro Rear Rim: 725 g (29’’)

- M9 Pro Wheelset: 2,236 g (29’’)

MSRP: $2,300

Intro

Carbon fiber mountain bike wheels are commonplace now, but it wasn’t all that long ago that they were a rarity. Enve arguably did more than any other company to bring carbon wheels to the mountain bike world, but their flagship M-Series wheels had grown long in the tooth and were notably stiff / punishing compared to many of the newer, more compliant options out there.

However, Enve’s new, fifth-generation M-Series wheels promise dramatically lower stiffness, and Enve has some eye-popping numbers to back that up. There’s a lot of interesting stuff going on with the design of the new wheels, which span a wide range of use cases from XC to DH racing, including new Enve-designed hubs.

For a whole lot more on the backstory behind the development of the new M-Series wheels, check out Ep.243 of Bikes & Big Ideas with Jake Pantone from Enve. Here, we’re going to focus on the design of the new wheels. Let’s see what Enve has come up with.

Design Overview — M-Series Wheels & Hubs

We’ll start with the aspects that are common to all four of the new M-Series wheels, before diving into the separate models individually.

Unsurprisingly, the rims are all made from carbon fiber in Enve’s own facility in Utah. There’s also a distinct commonality in their overall profile, with the rim cross sections all being much shallower than the prior-generation versions. They also feature convex sidewalls that Enve says help achieve their ride quality goals for the new wheels — specifically, much, much lower stiffness than the outgoing versions.

As with most modern wheels, the bead seats are hookless, and all four M-Series wheels get dedicated front and rear rims with different carbon layups and different geometry (apart from the DH-race-oriented M9 Pro) to tailor their ride feel and make for a stronger rear rim while saving weight from the front where possible.

The gen-5 M-Series wheels still have their spoke holes molded in rather than drilled, which Enve says helps with rim strength by not cutting fibers during drilling. Unlike prior M-Series wheels, the gen-5 wheels’ nipples are now external for easier truing and replacement of broken spokes. The one thing that’s not conventional about the nipples is that they now feature nyloc inserts, which Enve says are needed to help prevent the nipples from coming loose under normal riding due to the highly compliant nature of the new wheels.

The final big change across all four M-Series wheels is that they now use Enve’s own Innerdrive hubs, rather than being built with a variety of third-party options. The Innerdrive hubs have actually been around for a little while on Enve’s drop-bar wheels, but this is their first MTB application. The mountain bike versions use the same star ratchet style internals as the drop-bar versions but with different hub shells and axles tailored for MTB use.

The entire ratchet mechanism is retained in the hub shell by a snap ring, so there’s no risk of parts falling out if you take off the wheel trailside. Bearing preload is automatically adjusted by a wave spring that’s sandwiched in the middle of the axle so that no manual adjustments are required. The Innerdrive hubs use notably large 42 mm diameter ratchet rings, which are positioned directly over the hub bearings to reduce side loading and prolong bearing life. All of the M-Series wheels come stock with an 80-tooth ratchet ring pair, but Enve offers 40, 60, and 100-tooth versions separately if you’d prefer faster engagement, or a slight decrease in drag by opting for one of the slower-engaging options.

All the M-Series wheels (M9 Pro excepted, for reasons we’ll get to shortly) also come pre-taped with Enve’s new tubeless rim tape. They say this tape is more flexible and offers better adhesion than their earlier offerings without leaving any residue on removal. It’s also available separately in 10 or 50-meter rolls and in 25, 27, 29, 32, 34, 36, and 39-mm widths for use on a wide range of rims, Enve or otherwise.

All of the M-Series wheels come with a five-year warranty and incidental damage protection plan. Any damage that’s deemed to be the result of defects in materials or workmanship is covered — including for secondhand owners — for five years from the original date of purchase. Damage that’s incurred for any other reason is covered in full for three years; the coverage drops to a 50% discount in the fourth year and a 35% one in the fifth.

Enve M5 Pro Rims & Wheels

At the lightest-duty (and just lightest) end of the range is the M5 Pro, Enve’s XC race wheelset; it replaces the M525 in that role.

In keeping with modern trends in XC race wheels and tires, the M5 Pro has grown wider, to 29 mm front / 27 mm rear internal width, from 25 mm on the M525. Despite that, the M5 Pro wheelset comes in a little over 80 grams lighter than the M525, at a stated weight of 1,341 grams for the pair. The bead seat walls are notably wide (4.2 mm front / 4.7 mm rear) to help with pinch-flat resistance, and despite the reduction in weight, Enve claims a 30% increase in impact strength compared to the M525.

[For the record, the “Pro” part of the M5 Pro designation just means that the M5 Pro, along with the M9 Pro, was developed in close collaboration with Enve’s pro racers. The stuff they learned from that development, in turn, informed the design of the M6 and M8, but they’re all built to the same standard, and all cost $2,300 for a pair. More on the other variants in a minute.]

The cross-section height of the M5 Pro rims has been decreased dramatically from the M525, to 20 mm from 25. The concave sidewall design that Enve is using across the new M-Series wheels also makes the cross-section height shallower across much of the width of the rim. In conjunction with tweaks to the carbon layup, this makes for a much less stiff rim than the M525, with Enve claiming a 25% reduction in vertical rim stiffness (i.e., for the rim on its own, not laced into a wheel) and a 52% reduction in lateral stiffness.

The M5 Pro is offered in 29’’ diameter and with Centerlock rotor mounts only, with 110 x 15 mm front and 148 x 12 mm rear axles. The M5 Pro wheels use 24 Sapim CX-Ray bladed straight-pull spokes and aluminum nipples front and rear.

Enve M6 Rims & Wheels

Moving up a rung in intended use, the M6 wheels are Enve’s all-around Trail bike wheels, replacing the M630, M635, and M640 in that role.

Plus-sized tires were at the height of their (limited) acceptance around when Enve launched the prior-generation M-Series wheels in 2018, but with their demise and the convergence of modern tire sizes to a fairly narrow band, Enve has dropped the options for different rim widths. The M6 gets a single 32 mm front / 29 mm rear (internal width) pairing.

The profile of the M6 rims is similar to that of the M5; the M6 rims are just a touch wider and fractionally taller (at 20.8 mm instead of 20 mm). The M6 shares the wide bead walls of the M5 (still 4.2 mm front / 4.7 mm rear) and uses the same straight-pull Sapim CX Ray bladed spokes, just with 28 of them per wheel, and paired with brass nipples.

The stated weight for the M6 wheels is within 3 grams of the M630 pair, but Enve says that the M6 is 47% more impact resistant, while also being 50% less stiff vertically and 48% softer laterally (again for the rims on their own, not laced into wheels).

Like the M5, the M6 uses Centerlock hubs only, but the M6 is available in your choice of a 27.5’’ or 29’’ rear wheel (the front is still 29’’ only) with either 148 or 157 mm rear hub spacing and your choice of Microspline and XD drivers.

The M6 wheels are rated for ASTM Category 4 usage, and Enve condones their use on eMTBs with up to 75 Nm of torque.

Enve M8 Rims & Wheels

The M8 is Enve’s lighter ‘gravity’ wheel, aimed primarily at Enduro bike use, but it’s also rated for ASTM Category 5 level abuse on DH bikes. Most of the M8’s general design features and philosophy carry over from its lighter-duty siblings, including the overall rim profile with concave sidewalls, the 32 mm front / 29 mm rear internal width from the M6, and the notably wide bead wall (4.2 mm front / 5.1 mm rear).

Like the M6, the M8 wheels are available in 29’’ front diameter only, with either a 27.5’’ or 29’’ rear, in either 148 or 157 mm spacing. The front wheels are available with either 110 x 15 mm axles (which get a Centerlock rotor mount) or 110 x 20 mm ones (which are six-bolt). Enve says a conversion kit to adapt the 20 mm hub down to 110 x 15 mm will be available by December. You can have your choice of rotor mount standards on the 157mm-spaced rear wheels, but the 148 mm versions are Centerlock only.

Stated weights for the M8 rims are 537 g (front) and 585 g (rear). You get a stated wheelset weight of 1,983 g in full 29’’ guise when you add in the M8’s Innerdrive hubs (in a J-bend flange spoke design), 28 Sapim Sprint spokes up front, 32 of the same on the rear, and brass nipples all around.

Unlike the wheels they most directly replace, the M730, the new M8 wheels don’t use Enve’s molded polyurethane rim strip, and instead go with conventional rim tape. Despite that change, the M8 wheelset comes in about 30 g heavier than the M730, but Enve says that the M8 rims are ~21% stronger than the M730s in their impact fatigue testing. In their single impact testing, the M8 displays damage slightly sooner, but the failure mode is much less catastrophic. At the point of failure in their square-edged impact test, the M8 develops a small crack but is rideable; the M730 gets a full cross-sectional failure and is done.

Enve’s claimed reductions in rim stiffness for the M5 Pro and M6 are already dramatic, but things start getting really wild with the M8 — Enve says that they’re 73% less stiff vertically and 47% less so laterally than the M730. The M8 wheels are also condoned for use on all eMTBs.

Enve M9 Pro Rims & Wheels

Finally, the M9 Pro is Enve’s heaviest-duty gravity race wheel. In addition to seeking significant ride quality improvements over the M930 wheels that they replace, Enve established a goal of “No Lost Runs” during the M9’s development. Enve says the M9 wheels have made it to the bottom of every timed training, qualifying, and race run for all of their World Cup downhill athletes without catastrophic rim failure or tire pressure loss over both the 2023 and 2024 seasons.

To that end, the M9 wheels use Enve’s polyurethane rim strip, which takes the place of conventional rim tape but also wraps over the rim sidewalls to widen the rim wall and add some cushioning to prevent pinch flats. Enve claims that the M9 Pro rim fails before a pinch flat occurs in their lab testing, and says that the molded rim strip means that the tire won’t lose air if the rim is merely cracked since the air chamber is fully isolated from the rim.

Those rim strips do come with a weight penalty; the M9 rims weigh a portly 720 and 725 g (front and rear, respectively, 29’’ diameter). The M9 uses the same 28 front / 32 rear spoke counts and the same Sapim Sprint J-bend spokes with brass nipples as the M8 wheels, and that adds up to a stated wheelset weight of 2,236 g for the M9.

That’s pretty heavy, but Enve says that weight was not a priority for the M9 Pro wheels. Instead, they sought to prioritize ride quality and durability (including making the M9 Pro allegedly un-pinch-flatable).

The stiffness reductions that Enve has achieved with the M9 Pro (as compared to the old M930 rims) are even more eye-popping than those of the M8 — they claim a frankly bonkers 77% reduction in vertical stiffness and a 64% drop laterally.

The M9 Pro rims still get front- and rear-specific layups, but their internal widths are the same 29 mm at both ends. Including the required rim strip, the bead walls on both are 6.2 mm wide.

Like the M8, the M9 Pro is available with a 29’’ front wheel and either 110 x 15 mm front axle with a Centerlock rotor mount, or with a 110 x 20 mm axle and six-bolt rotor mount. The rear M9 Pro wheels are offered in all of the possible combinations of 27.5’’ or 29’’ diameters, 148 or 157 mm spacing, Centerlock or six-bolt rotor mounts, and Microspline and XD drivers.

Bottom Line (For Now)

Enve is adamant that their new M-Series wheels ride nothing like their predecessors while offering improvements in real-world durability, and we’ve started spending time on the M6 wheels to see how those claims stack up. BLISTER+ Members and folks with our Digital Access Pass can check out our early impressions of the M6 wheels, and we’ll also be getting a set of M9 Pro wheels in for testing soon as well. Stay tuned for much more on how they perform once we’ve been able to log more time on them.

Flash Review: Our Initial On-Trail Impressions

BLISTER+ members and those who purchase our Digital Access Pass can check out the Flash Review below to read our initial on-trail impressions. Get our Digital Access Pass to view all our Flash Reviews and Deep Dives, or become a BLISTER+ member today to get access to that and a LOT more, including the best worldwide Outdoor Injury Insurance, exclusive deals and discounts on skis, personalized gear recommendations from us, and much more.

Flash Review — Enve M6 Wheels

Enve says that their new M-Series wheels ride very differently from Enve wheels of old, and we’ve started putting those claims to the test with their new Trail bike wheels, the M6. Check out our early impressions.

Blister’s Flash Reviews and Deep Dives are accessible to those who purchase one of our paid subscriptions

To get our comprehensive Deep Dives and our initial, unfiltered reports on new gear, become a member and receive many other services, deals, and discounts.

If you’re already an active member, please log in.

(If you’re already logged in and a member in good standing and seeing this message in error, please refresh this page in your browser.)

As someone who just spent a lot of time looking for a DT ratchet ring, and was about to order a ~$120 replacement, all just because the cassette fell off while walking around with my spare wheel, I really like the snap ring idea!

Also all the other ideas sound great!

And brass nipples! Just had a wheel rebuilt because the alloy nipples had corroded.

Yeah, brass nipples should be mandatory on carbon wheels. Galvanic corrosion is brutal.