Project321 G3 Hubs

Stated Weight:

- Front: 155 g (Centerlock) / 175 g (w/ 6-Lock)

- Rear: 292 g (Centerlock) / 312 g (w/ 6-Lock)

MSRP (Hubset):

- Black: $650 USD / $875 CAD

- Color: $675 USD / $910 CAD

- Custom mix-and-match: $700 USD / $945 CAD

Configurations Available:

- Front: 110 x 15 mm Boost, 100 x 15 mm, 100 x 12 mm

Rear: 148 x 12 mm Boost, 157 x 12 mm Super Boost, 142 x 12 mm

Drive System: M-Pulse w/ magnetic pawls; 288 points of engagement

Blister’s Measured Weights:

- Front hub (110 x 15 mm Boost, Centerlock configuration): 155 g

- Rear hub (148 x 12 mm Boost, Centerlock configuration): 295 g

- 6-Lock adapters: 21 g each

Bolted To: Contra MC

Reviewer: 6’, 165 lb / 183 cm, 74.9 kg

Test Locations: Washington & British Columbia

Test Duration: 5 months

Intro

Project321 first showed off prototypes of their new G3 hubs at Sea Otter 2023, and the most attention-grabbing part of their design was the very slick 6-Lock rotor mounting system. But there’s a lot more going on with the G3 hubs than just the 6-Lock arrangement, including a revised version of their M-Pulse freehub mechanism with 288 points of engagement, a revised axle and bearing layout, and improved sealing. And they’re now made in Canada, too.

Let’s take a look at what Project 321 has cooked up.

Design & Options

Project321 offers the G3 hubs in 110 x 15 mm Boost, 100 x 15 mm non-Boost, and 100 x 12 mm front axle spacing, and with 148 x 12 mm Boost, 157 x 12 mm SuperBoost, and 142 x 12 mm non-Boost rear axles to fit most modern(ish) mountain and gravel bikes (fat bikes and DH ones with 20 mm front axles excepted). They’re available in 12 different colors, with the standard black option retailing for $650 USD / $875 CAD; going to a different colored hub shell bumps the price up to $675 USD / $910 CAD, and if you want to mix and match different colored end caps and / or 6-Lock flanges (more on those shortly) you can do so for $700 USD / $945 CAD.

6-Lock Rotor Mounting

The 6-Lock rotor mounting system is arguably the most novel (and visually obvious) way that the G3 hubs set themselves apart.

In short, the G3 hub shells are just configured for a standard Centerlock rotor. If you want to run those, go nuts — they mount up normally.

But if (like me) you prefer six-bolt rotors for their easier trailside serviceability and a greater array of rotor options, that’s where the 6-Lock system comes in. In principle, it’s just a different way of doing a six-bolt rotor adapter for a Centerlock hub, but in theory, it has some real advantages over a more conventional adapter (or a dedicated 6-bolt hub for that matter).

The way it works is pretty simple: there’s a stainless steel collet that snaps over the Centerlock splines on the hub, which includes threaded bosses to accept rotor mounting bolts. An aluminum flange slides over the Centerlock splines and onto the collet to support the rotor and transmit braking torque to the hub shell. A standard six-bolt rotor then bolts right up, and tightens the collet against the back side of the Centerlock splines on the hub shell to keep everything nice and secure.

Unlike a more conventional Centerlock adapter, the 6-Lock design means that you don’t need a bottom bracket or cassette tool to attach or remove the rotor, making trailside maintenance with a multi-tool more viable. Centerlock adapters also often have a slight amount of play in the interface, and the 6-Lock system should do away with that, too.

(The 6-Lock collet does use M4 bolts instead of the more conventional M5 rotor mounting ones, but Project321 includes custom ones with a T25 Torx head to make things easy. Finding replacements at a hardware store with that T25 head probably isn’t happening, but you should be able to make something work with an off-the-shelf bolt in a pinch.)

The 6-Lock design also means that the rotor bolts thread into a harder stainless steel piece (the collet) instead of a softer aluminum hub shell, making them harder to strip. And the collet is, of course, replaceable if need be.

M-Pulse Freehub Mechanism

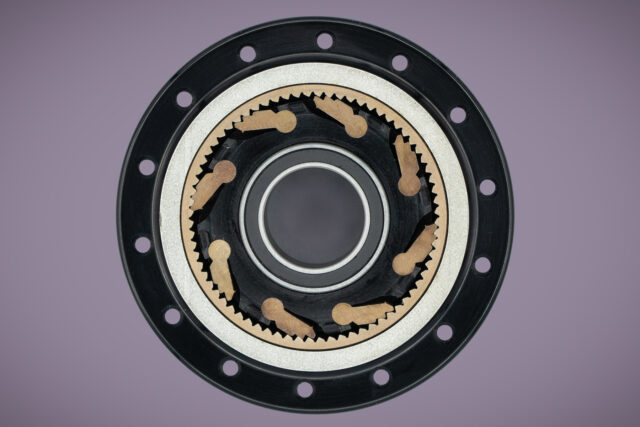

The G3 hubs also get an updated version of Project321’s M-Pulse freehub mechanism. In short, it’s conceptually pretty similar to the earlier iterations that we’ve seen in the Project321 G2 hubs (and ones from Stan’s as well) but with faster engagement (now 288 points / 1.25° rotation, from 216 points / 1.66°).

The M-Pulse freehub uses pawls (eight of them, phased to engage in four sets of two each) and a ratchet ring inside the hub shell, which is normal enough, but unlike most pawl-driven hubs, which use small springs to push the pawls into place, Project321 uses magnets. The main idea is to reduce drag by lowering the amount of friction between the pawls and the ratchet ring as they click over from one set of teeth to the next.

Project321 says that the M-Pulse design makes for appreciably lower drag when coasting compared to a more conventional hub design, and they’ve worked on the axle and seal layout to improve things on that front, too.

Axles, Bearings, and Seals

The G3 hubs use a new axle design that Project321 says is stronger than the older version they used on the G2 hubs. The rear hub spins on four cartridge bearings (two for the freehub and two for the main hub shell) with dual-row bearings used in the higher-load portions for the more heavily loaded inboard position on both. And unlike most cartridge bearing hubs, the G3 features adjustable bearing preload to keep things free of play without undue friction and bearing wear. The new axle design has already been used in Stan’s M-Pulse hubs since 2022, but the G3 is the first Project321-branded hub to receive the update.

FULL REVIEW

The Project321 G3 hubs have several novel features that sound compelling on paper, but do they realize their promise or are there drawbacks? I was eager to find out.

Installation

From an installation / compatibility standpoint, the G3 hubs’ novel 6-Lock rotor mounting system is by far the most interesting and unique aspect, so we’ll start there.

I was quite intrigued by the idea when I first saw it at Sea Otter a few years back, and having now used it, I’m a huge fan. I, frankly, am a bit of a Centerlock hater. I don’t like that it takes a mounting system (standard six-bolt) that both has redundancy and uses a tool that’s on almost every bike-specific multi-tool in the universe and does away with both of those benefits. And I don’t like that there are far fewer Centerlock rotor options, especially in larger diameters, though that is slowly changing.

Yes, Centerlock adapters are widely available to run six-bolt rotors on a Centerlock hub, but they don’t fix my first point about redundancy in the mounting, nor the ability to fix things trailside with a multi-tool. Many of them also have a little bit of play in them, which lets the rotor rock back and forth and creates a slight knocking sensation when you first get on the brakes.

But Centerlock rotors have their proponents, and we aren’t about to put that proverbial toothpaste back into the tube, which is where Project321’s 6-Lock system comes in. We already covered the design in our First Look, above, so I won’t rehash that here, but the 6-Lock system works exactly like I hoped it would. It gets you a Centerlock hub if you want it, but also what is effectively the best (by far) six-bolt rotor adapter I’ve tried to date if you don’t.

Unlike every other adapter I’m aware of, the 6-Lock system doesn’t rely on a conventional Centerlock lockring to hold everything in place, so it fully solves my complaints about tool compatibility and the ability to tighten things up trailside if needed. There’s also no detectable play in it at all. It’s the only system I’ve seen that truly gives you what is functionally a normal six-bolt hub with the ability to still run a Centerlock rotor if you want. If I can’t just banish Centerlock to the dustbin of history, that’s a sweet compromise.

The only minor downside is that the 6-Lock system uses custom M4 screws (with a normal T25 Torx driver) instead of the more conventional M5 ones on true six-bolt hubs. I haven’t had any trouble with the smaller bolts on the G3 hubs, but it would be nice if they used more widely available normal bolts. On the plus side, the 6-Lock system puts the rotor mounting threads in a replaceable collet rather than the hub shell itself, so they’re easily replaceable if you get ham-fisted and break or strip one.

Also, to be fair to Project321, normal six-bolt hubs use the bolts “wrong” from the standpoint of engineering best practices. Normal six-bolt hubs use the bolts in shear to bear all the braking forces, rather than sending that through separate standoffs and only using the bolts for clamping everything together. Going down to M4 bolts let Project321 use them in the technically correct way. That said, there’s very proveably enough of a safety factor in the standard layout for it to not really matter, and it would be more convenient if they used M5 bolts instead. That said, you could definitely just use a normal M4 button-head screw from any hardware store with a washer under its head in a pinch, so it’s not that big a deal.

Otherwise, there’s (unsurprisingly) not a ton to report on the installation front. The hub flange geometry is tidy and the G3 hubs built up easily (laced to We Are One Triad rims in this case). The front hub endcaps just press into the bearings, but there’s a solid enough detent that I haven’t had issues with the non-drive-side endcap pulling off with the axle and getting stuck when using a fork with a floating axle design (e.g., a Fox 38 or EXT Era). That can be a minor nuisance on some other hubs (most notably Industry Nine 1/1s, in my experience).

My only other minor gripe is that I’d love it if Project321 used slightly larger bearings in the front hub so that it could be converted to a 20 mm axle, but with a 17 mm bearing ID, that’s not an option.

On-Trail Performance

There’s not a ton to say about the G3 front hub, which is really for the best. For front hubs in general, there’s little enough going on with them that it usually just breaks down to “I had problems” or “they worked great and I never had to think about them.” The G3 hubs, happily, fall into the latter camp.

The front hub endcaps basically serve as a dust shield over the bearings, but there are no contact seals built into the hub itself (which is pretty common). The bearings are reasonably clean and still feel very smooth after five months of use in a mix of very dusty and then quite wet conditions. Still, I might recommend another hub (Hadleys, probably) if you specifically want the most robust secondary sealing and are willing to take a bit of a weight penalty for it.

Things get a lot more interesting in the rear hub. There, the G3 hubs use a pawl-driven layout but use magnets embedded in the pawls themselves to draw them into the drive ring, rather than relying on a spring. Project321’s approach (theoretically) has some benefits in reducing noise and drag, as we discussed in our First Look.

And it works. The G3 hubs are neck-and-neck with Hadleys and DT Swiss’s new Ratchet DEG hubs for the quietest-ratcheting hubs I’ve tried to date (apart from the truly silent Onyx ones, which use a sprag clutch ratchet mechanism). The G3s are higher pitched than the Hadleys and Ratchet DEG hubs, probably due to the G3’s much faster engagement (288 points vs 72 for Hadley and 90 for the Ratchet DEG). Still, all three are notably quiet, to the point of not being audible at all when moving fast enough to generate a little wind noise. I’m squarely in the camp of wanting the quietest hubs I can get, and the G3s are very good on that front.

The G3 rear hub also feels noticeably low on drag if you A-B it against a hub with even higher engagement, such as the Industry Nine Hydras. It’s a subtle difference, especially on a burly Enduro bike running heavy, aggressive tires, but it’s there. Being able to precisely adjust the G3’s bearing preload probably helps in that regard, but I think the magnetic drive system deserves much of the credit. Particularly for such a high-engagement hub, they’re quite smooth and low drag.

I’m widely on the record as saying I don’t care much about chasing the absolute most points of engagement that I can get (the G3’s 288 points are way more than enough for my taste), but there aren’t many downsides to having that many if it doesn’t come with much of a drag penalty, and the G3s do especially well in that regard.

Durability

I’ve got very little to report here — the G3 hubs have held up quite nicely after several months of use. The grease in the freehub isn’t entirely clean, but it’s still doing its job effectively, and I haven’t seen the need to do anything about it yet. I did have the preload adjustment collar on the rear hub come loose after a ride or two, but applying a little bit of blue thread locker and tightening the clamp bolt a touch more snugly took care of that; I haven’t needed to touch it since.

The bearings are all still in great shape, and I’ve had no issues with the rear hub skipping or anything like that. Since that initial tightening of the preload collar, the G3s have just let me get on with my riding and I haven’t needed to think about them at all.

Bottom Line

I’m a big fan of Project321’s G3 hubs. Their 6-Lock system is genuinely brilliant, they’re pretty light, they offer especially high engagement without much drag or noise, and they’ve held up very well so far.

I’d love it if there was a 20 mm front axle option, and for the 6-Lock system to use M5 bolts instead of M4s. The former won’t matter for most folks (which is unfortunate; 15 mm axles should never have happened…), and the latter is only a theoretical annoyance rather than one that has actually mattered one bit.

They’re not cheap, but Project321 has made a genuinely unique offering in a space where unique designs are hard to come by. Plus, the places where Project321 took a novel approach have genuine benefits — they’re not just being different for the sake of being different. If you don’t need a 20 mm front hub, the G3 hubs are a very compelling option for a high-end, high-engagement pair of hubs.

I’ve got a set of G2s laced to Astral Serpentine Carbon rims with about a billion miles on them.

Unflappable, after replacing the early-days rear axle with the beefier version. These G3s look like they’ve improved even more in the sturdiness area.

In regards to the POE you mention that “there aren’t many downsides to having that many [POE]”; did you not notice any additional pedal kickback with the higher POE hub?

Well, the Contra MC that I tested on has very little pedal kickback. But I’ve tried ultra high engagement hubs (Hydras more than anything else) on a bunch of bikes over the years and my general take is that you have to go very, very low engagement to make a meaningful reduction. And even so, it’s not consistent in the effect – you’re essentially just randomizing the benefit between “some” and “none” depending on where the ratchets happen to be at the instant that you experience a big compression.

Great follow up to your early review/first look/whatever.

I can report that the G2s laced to Astral Serpentine Carbon rims with about a billion miles on them I mentioned above, in April, now have even more miles on them, and are still going strong.

I’d buy these again in a heartbeat, should my Astral Serpentine Carbon wheelset ever wear out.