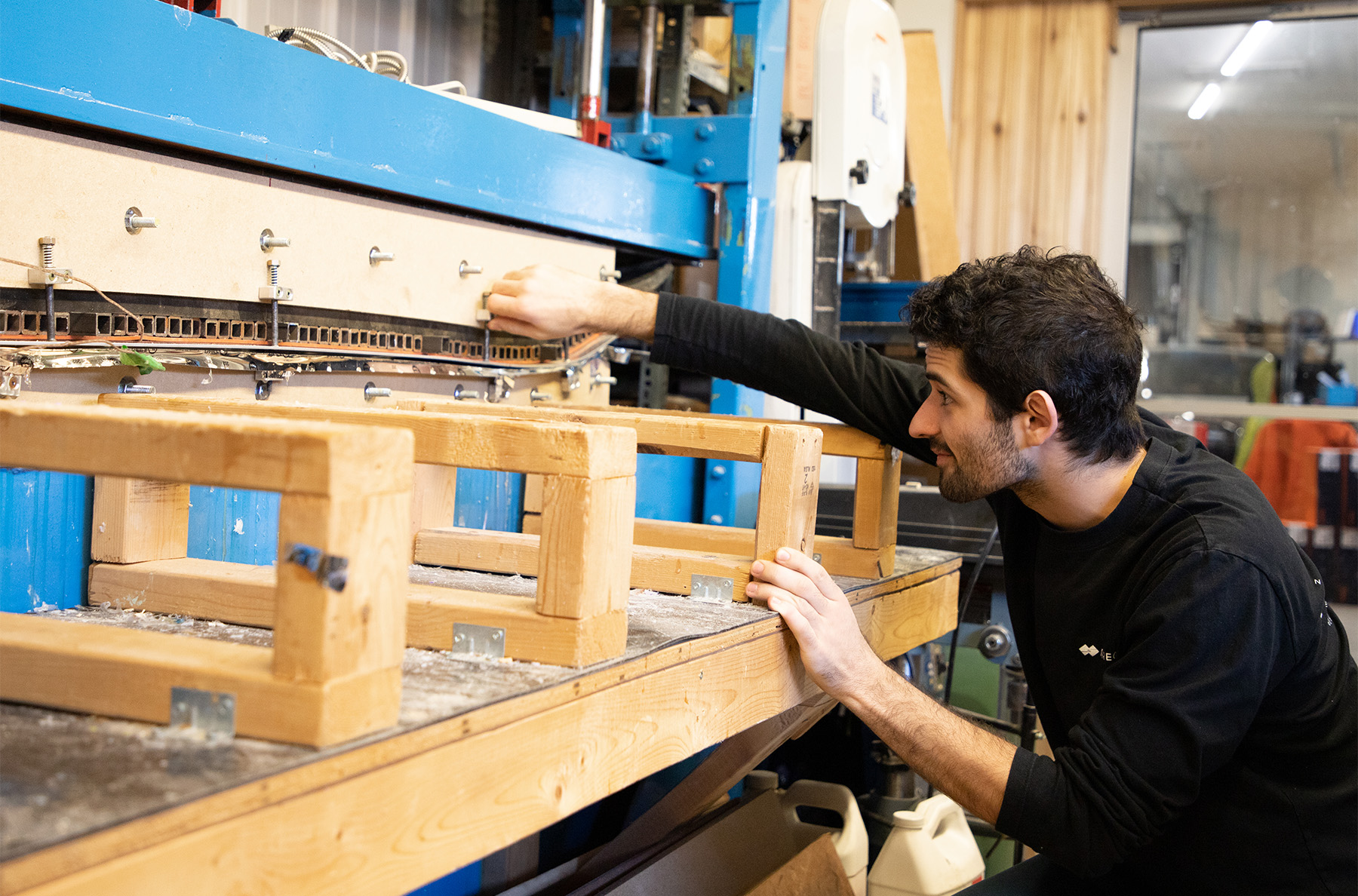

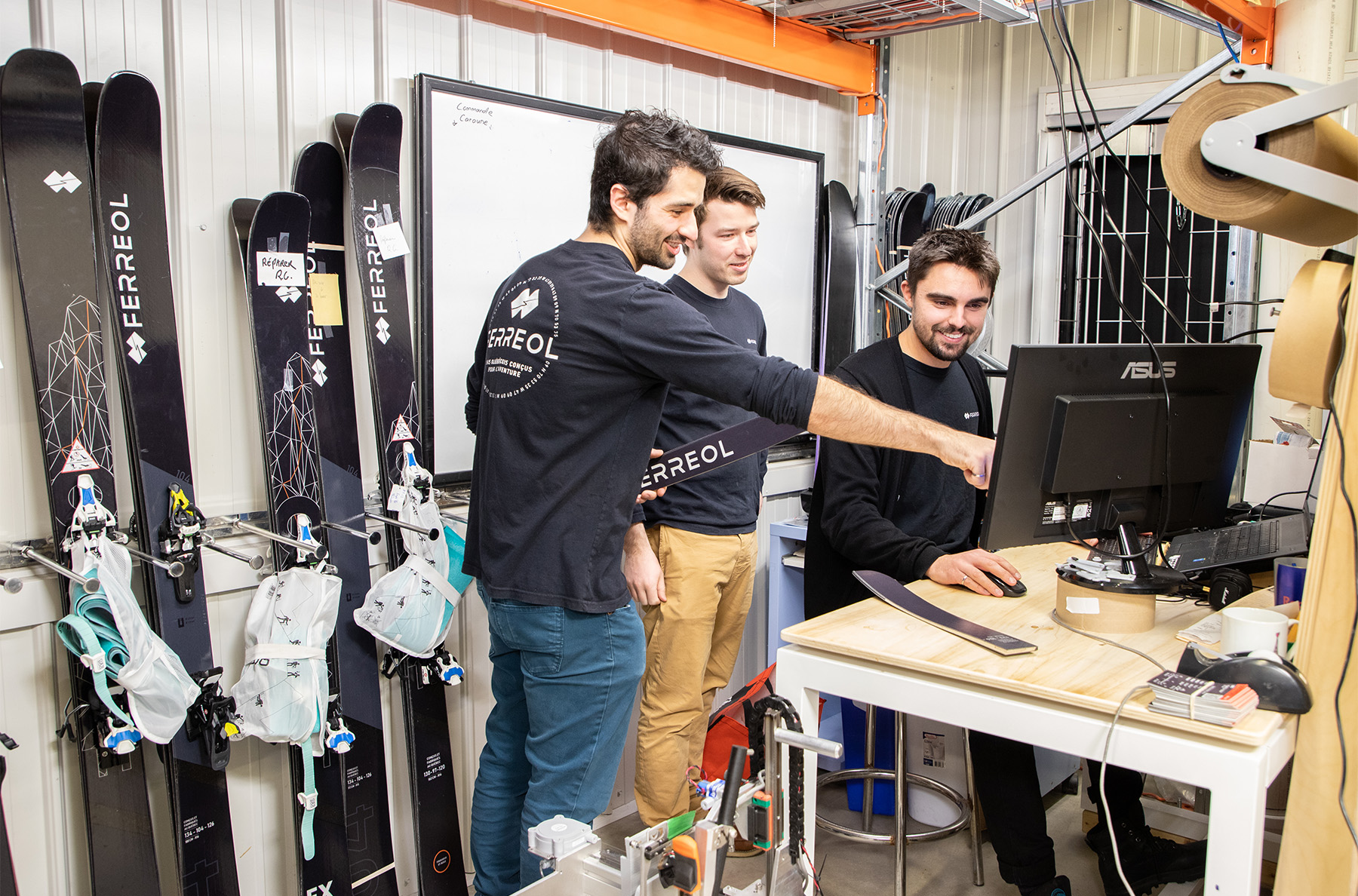

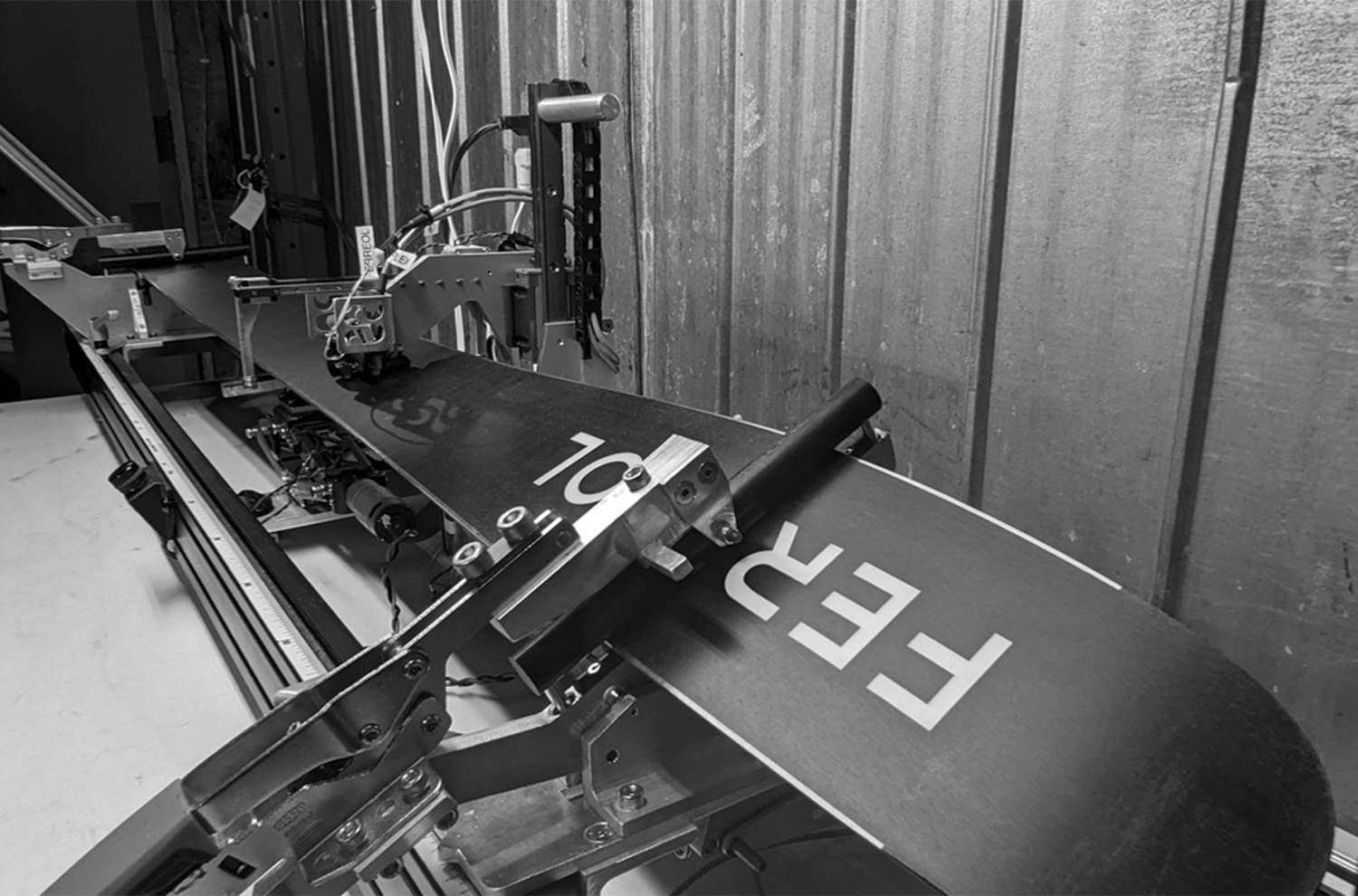

Ferreol is a relatively new company that designs and builds skis in Quebec, and they are working hard to push beyond conventional ski materials and construction. They created their own “Innovation Lab” to not only test skis but also develop new materials — and they’re not keeping it to themselves. Instead, they’re collaborating with other brands in order to move things forward at a greater scale.

So I sat down with Ferreol co-founder, Jonathan Audet, to discuss all of that, including the development of their own alternative to titanal alloy; fully replacing fiberglass with natural flax fibers; their 23/24 ski lineup, and more.

TOPICS & TIMES:

Origins of Ferreol (3:38)

Blindspots in the Market (7:00)

Replacing Fiberglass w/ Flax (8:45)

Life Cycle Analysis (11:24)

Ferreol’s 23/24 Lineup: (19:18)

Surfer 112 (19:18)

Pioneer 104 (23:19)

Explo 96 (28:26)

ZigZag 92 (30:43)

Ferreol Innovation Lab: Background (34:01)

Developing an Alternative to Titanal (36:49)

Ski Design App (50:13)

Ferreol Skis: Who Should Get Them? (51:45)

What We’re Celebrating / Crashes & Close Calls (59:37)

RELATED LINKS:

BLISTER+ Membership

23/24 Blister Winter Buyer’s Guide

Blister Summit Registration

CHECK OUT OUR OTHER PODCASTS:

- CRAFTED

- Blister Podcast

- Bikes & Big Ideas

- Off the Couch

- Happy Hour (for Blister Members)

So many skis on the market today. It is mind boggling.

I would love to see these guys at the Blister Summit!

Titanal is fairly similar to Al-7068. I tracked down AMAG’s patents for Titanal, and the composition matches Al-7068 reasonably closely, as does the (fairly exotic) process required to create it. 7068 is a state-of-the-art alloy used in aviation and military ordnance, and has benefitted from gazillions of dollars in R&D, so I’ll believe that Ferreol has significantly bettered that in terms of yield strength (what he claimed in the podcast) that when I see the third party measurements.

If Ferreol truly has bettered 7068/Titanal then they’re wasting his time by solely targeting the ski market, since they could make billions in other higher-volume/margin markets.

The reason why Titanal has been so dominant in skis is because of that phosphate-annodized surface treatment that enables reliable bonding in a ski laminate (aluminum is nearly impossible to bond unless you do something to increase surface energies). If it weren’t for that ski makers would just buy 7068 from Kaiser since it’s fair cheaper and easier to procure. I will be interested in seeing how Ferreol’s new treatment competes with that in wide production.

One other note: A thicker ski with 2 0.3 mm layers may have similar stiffness to a thinner one with 2 0.5 mm layer, but the “feel” is radically different in terms of suspension/dampness. That’s why racing skis (and heavily race-influenced ones like the Pro Rider) tend to go for thinner cores and thicker metal layers

Also thinner metal layers are inherently more resistant to deformation than thick ones. This is basic beam mechanics. Titanal is perfectly capable of being used in 0.3 mm layers, IIRC that’s exactly what Faction does in the Dictator/Dancer line. The reason why a lot of makers used thinner cores with 0.5 mm layers is because they don’t want to make skis that feel like the Dictator.